Solution Paper

Bridge Solution for Prototype Manufacturing and Small Series Production

An End-to-End Solution for Prototype Manufacturing And Small Series Production

Solution Highlights

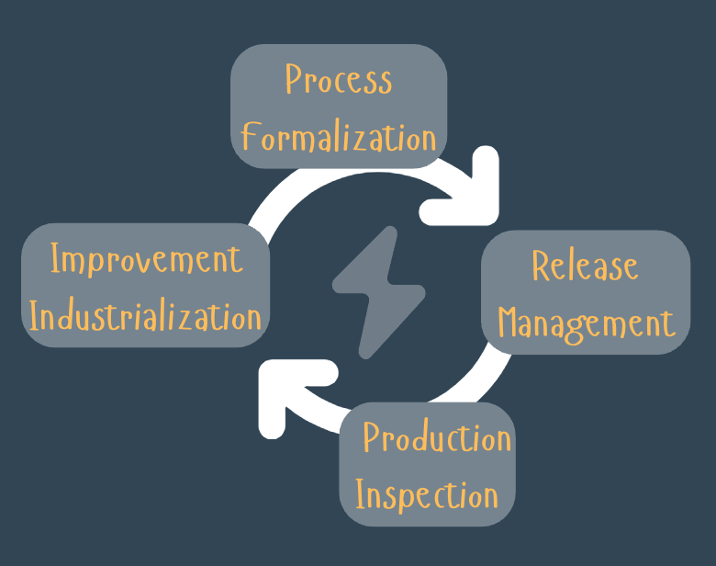

Bridge provides a comprehensive digital platform that enhances every stage of prototype and small-batch manufacturing processes, from process formalization to production inspection and continuous improvement.

- Process Formalization

- Define Standard Operating Procedures (SOPs) using various media: Office/Google files, PDFs, CAD links, Bridge step-by-step execution routings, checklists, and workflows.

- Integrate BOM and routing definitions from ERP, PLM, or Manage them in Bridge directly.

- Release Management

- Utilize role-based, sequential, and parallel approval workflows to validate SOPs.

- Maintain an audit trail capturing versions of “as-designed” state.

- Production & Inspection

- Release and dispatch orders directly from ERP (or Manage order in Bridge).

- Automatically retrieve appropriate SOP versions and assign tasks to production lines.

- Manage production sequencing and create serial numbers effortlessly.

- Track resources, tools, and machine parameters.

- Use electronic work instructions to drive execution, capture data and build traceability through manual inputs, scans, sensors, or PLC integrations.

- Manage quality inspections and production events in real time.

- Achieve full end-to-end traceability with reports shareable with clients or partners.

- Improvement & Industrialization

- Modify BOMs and work instructions during order execution with traceability.

- Leverage SOPs for production, training, and new product introductions.

- Utilize data for SPC, root cause analysis, and CAPA workflows.

Business Value

- Drive efficiency, repeatability, and speed while minimizing errors.

- Structure SOPs and product introduction processes with versioned specifications, electronic approvals, and enforced execution.

- Use data insights to enhance industrialization.

Implementation Highlights

- Typical implementation duration: 2/3 months, mainly remote.

- A collaborative approach to empower business owners and configure solutions without heavy IT involvement.

- Cloud, on-premises, or hybrid deployment options with minimal IT dependency.

TCO Optimization

- Agile, packaged solution with no development required. The configuration stays in the hands of business users.

- Leverage existing infrastructure and open-source technologies to keep costs low.

- Periodic updates ensure clients benefit from the latest features without accumulating technical debt.

ROI Targeting Self-Funded Projects

- Incremental deployment to capture immediate returns.

- Cost directly tied to usage, with no upfront fees, enabling a self-funding model.

Risk Mitigation

- Proven success in over 130 plants across 25 countries with more than 25,000 daily users.

- No long-term commitment required; stop the subscription anytime.

- 24/7 support and ISO-certified processes for development, implementation, and support.