Bridge enables progressive, fast and self-funding digital transformation

Bridge at a glance

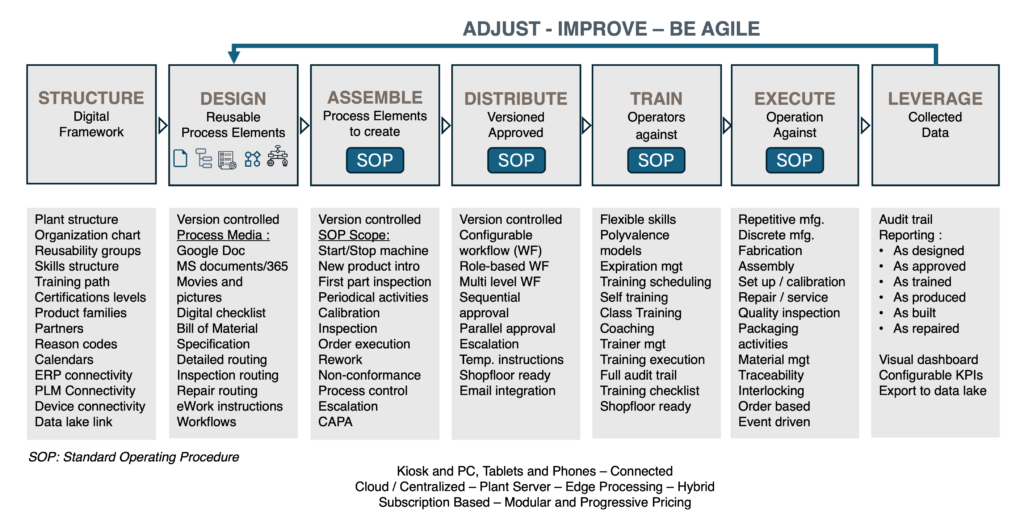

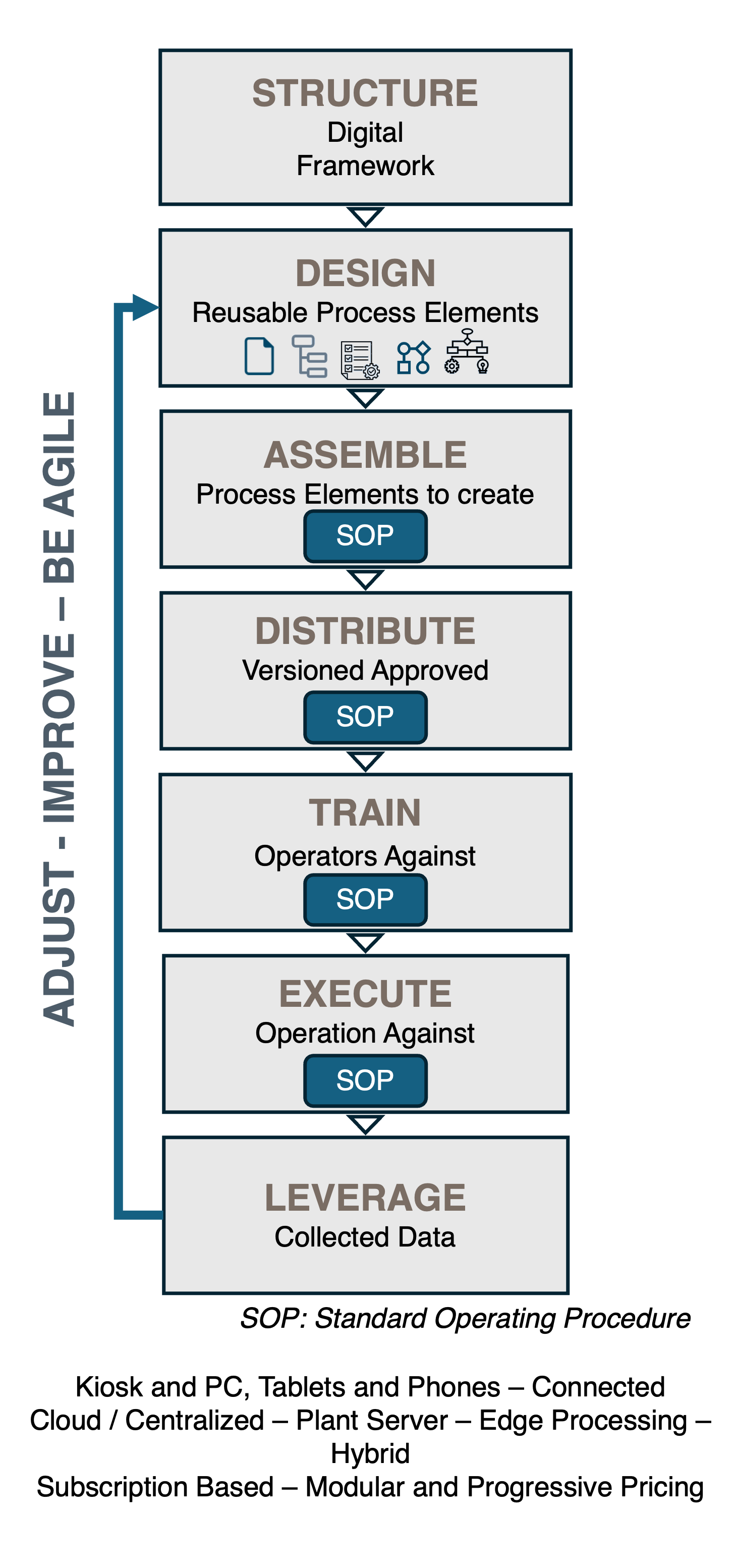

Bridge offers a comprehensive and modular feature set that empowers business users to gradually implement digital manufacturing processes.

Start by addressing critical pain points and expand as your digital maturity grows. Go live in just a few weeks and maintain agility, with complete control of the configuration in the hands of your process owners.

Business Solutions

Bridge is designed to deliver value directly to individual departments while also streamlining processes across the entire enterprise.

Thanks to its quick initial implementation and progressive pricing, Bridge is utilized by small, medium, large, and global manufacturers.

Bridge in numbers

Vision and Differentiators

Drawing on years of expertise in designing, developing, and deploying manufacturing software across hundreds of facilities worldwide, we have effectively eliminated the key obstacles to digital transformation.

Industry 4.0 offers are too often for fully connected, automated and autonomous plants, and don’t address very well transition phases.

Bridge was architected to optimize network consumption, server power, data storage and relies on open source third party software for database and operating system.

It leverages commonly shared, proven technologies for a low running cost platform.

Managing digital continuity between engineering, quality and manufacturing by integrating deeply PLM and MES is for most industrials too complex and at the end not affordable.

Bridge covers both Process modeling and Execution. It offers a smother and easier way to transfer engineering directions to the shop floor compared to the fully integrated PLM-ERP-MES vision that is very costly to implement.

A progressive pricing (real progressive SAS model), low running cost platform (infrastructure, DB, OS…) and limited upfront project costs make Bridge a very affordable and attainable solution.

Bridge can be mostly implemented and deployed by the business team members with limited support required from IT.

It makes the solution light to implement and extremely agile.

The architecture of Bridge is the result of 25 years of lessons learned deploying and manufacturing systems around the world. It is simple to implement, monitor and upgrade.

Every day, somewhere in the world, a plant upgrades to the latest version of Bridge without any reported issue.

Bridge has been architected to deploy via containerized components allowing it to be deployed in cloud infrastructure of choice, on-premises, or combined.

Relying on proven security protocols and frameworks, Bridge has been trusted by Fortune 500 companies to support their manufacturing operations.

Software Components

Implement each component of Bridge individually as a standalone solution point, or combine the components to create an end-to-end solution.

Target higher value and most critical pain points first, then expand as required

About

At Bridge, we leverage our extensive experience and cutting-edge open-source technologies to remove the main obstacles to digital transformation:

- Eliminating prohibitive initial investments that undermine the business case.

- Reducing lengthy and resource-intensive projects that delay value realization and complicate staffing.

- Simplifying complex solutions with a step-by-step approach that allows for immediate benefits from incremental improvements.

- Enhancing flexibility and reducing dependency on IT or external expertise, thereby increasing industrial agility.

We believe there is a better way to address Digital Manufacturing.

Our commitment to continuous improvement is reflected in the on-going enhancements of the Bridge solution, developed in close collaboration with our clients. Every day, somewhere in the world, a new site adopts the latest release of our software.

Recognizing the mission-critical nature of our solutions for our clients,

we provide 24/7 support with industrial-grade Service Level Agreements.

Unlike many competitors, Bridge is designed to be implemented directly by business owners, with minimal external help or IT assistance, making it both efficient and cost-effective.

the founders

Yves Vergnolle

Founder and CEO

Yves Vergnolle is an innovative and multicultural leader with over 25 years of experience in designing, implementing, and supporting manufacturing solutions. He has successfully guided numerous companies worldwide in defining and deploying their Digital Manufacturing strategies.

As a passionate software designer, Yves was a key originator of Apriso-FlexNet and has developed dozens of manufacturing solutions across various industries.

Krzysztof Heim

Founder and CTO

Krzysztof has over 15 years of experience at Apriso, designing and implementing large MES solutions for various customers. His dedication to software improvement led him to become the R&D Director at Dassault Systèmes, where he oversaw frameworks and packaged solutions.

In his spare time, Krzysztof enjoys working with microcontrollers, IoT devices, and 3D printers, which complements his daily work by enhancing the creativity of the solutions he builds with his team.

the Team

Contact Us

Contact us if agility and technology are critical to the performance of your operations.

Bridge is deployed in 27 countries. Our Solutions Development and Support office is located in Poland: ul. Michała Bobrzyńskiego 12, 30-348 Kraków, Poland.